3D PRINTING TROUBLESHOOTING

On this page, we’ve gathered common 3D printing issues with Paragami designs and provide practical tips to ensure smooth, successful prints.

001. GAPS IN THIN OR SINGLE-PERIMETER WALLS

-

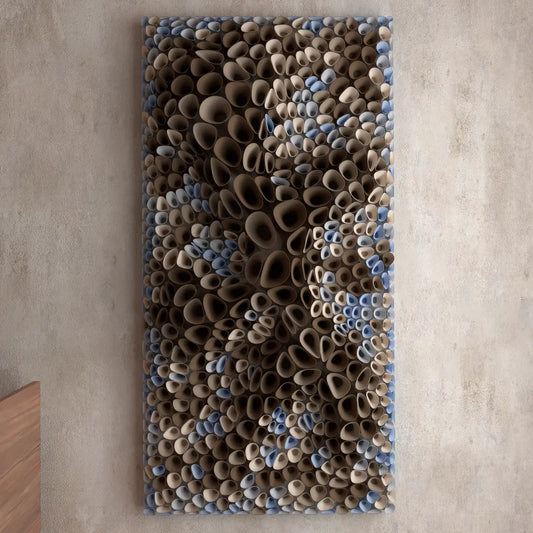

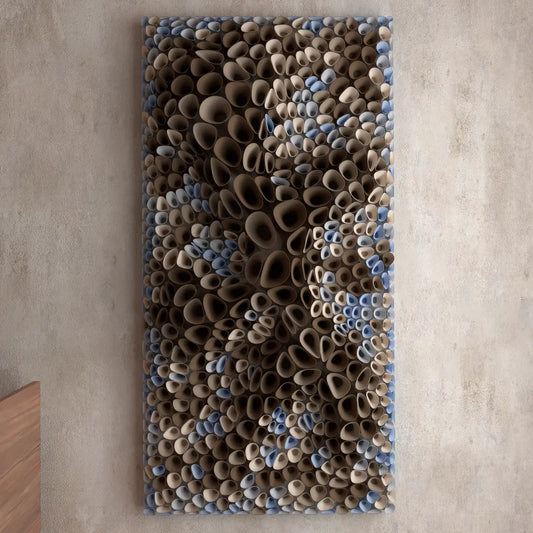

This issue most commonly affects Coral Sponge templates and other designs with thin, organic walls.

Some slicers struggle to generate continuous perimeters when a wall transitions between:

• Thicker sections (2 or more perimeters)

• Thinner sections (1 perimeter or near the slicer’s minimum wall width)

Instead of creating one continuous closed perimeter first, then adding extra perimeters where space allows, some slicers generate two perimeters simultaneously in thick areas, then a separate single perimeter in thin areas.This leads to:

- Gaps in the wall

- Disconnected perimeters

- Weak or unstable prints

Additionally, if a wall is thinner than the slicer’s minimum wall width, the slicer may skip generating a perimeter entirely.

- Gaps in the wall

-

-

What We’re Trying to Achieve (The Goal)

Regardless of slicer, the goal is always the same:

✔ A continuous, closed perimeter

✔ At least one perimeter generated everywhere the wall exists

✔ Smooth transitions between thin and thick wall sections

-

-

-

How PrusaSlicer Handles This

PrusaSlicer generally produces the correct behavior by default.

It:

- Generates a fully closed perimeter first

- Adds extra perimeters only where wall thickness allows

- Handles thin-wall transitions more predictably

- Generates a fully closed perimeter first

-

-

Suggested Adjustments for

BAMBU Studio & ORCA Slicer

Bambu Studio and Orca Slicer can achieve similar results, but often require manual tuning.⚠️ These settings are suggestions, not guarantees.

Every model/block is different, and you may need to tweak values. -

-

-

Enable Advanced Settings:

To get access to extra settings in Bambu Studio / Orca Slicer , make sure to enable Advanced or Expert mode.

-

Core Wall & Transition Settings

• Wall Generator: Arachne

Dynamically varies line width to better fill thin and variable walls

• Wall Transitioning Filter Margin: 1000%

Allows more aggressive smoothing between thick and thin walls

• Wall Transition Length: 150%

Extends the blending distance when changing wall thickness

• Minimum Wall Width: 150%

Forces generation of a perimeter even for very thin walls

• Minimum Feature Size: 50%

Prevents small wall features from being discarded

• Seam Position: Random

Avoids visible seam alignment and reduces weak points• Ensure vertical thickness: Enabled

These settings work in combination. Changing only one may not be enough.

-

Additional Techniques If Gaps Persist

If the above settings don’t fully solve the issue, try one or more of the following:

Thin Wall & Geometry Adjustments

- Enable “Ensure vertical shell thickness”

- Quality / Line Width / Outer wall:

Example-Reduce : 0.45 mm → 0.30 mm

In testing, I was able to successfully print a single block with a hole just by reducing the line width, while leaving all other settings at default (Wall Generator: Classic).

- Enable “Ensure vertical shell thickness”

-

-

Orientation & Print Strategy

Reorienting the model can significantly improve thin-wall printing. Tilt the model and enable supports so the problematic wall prints at a slight angle—this effectively increases the wall’s printable width and helps the slicer generate a continuous perimeter.

For low-rise or shallow-angle features, hollow blocks often print more reliably than solid ones. You can drag, drop, and rotate blocks to find an optimal rise angle; this approach works for both single blocks and grouped layouts (such as 4×4 arrays—split the group after rotating if needed).

Adjust the rotation based on your printer’s cooling performance and print speed. Fine-tune slicing accuracy by tweaking Detect Thin Walls, Shell Thickness, and Extrusion Width as needed.

When using supports:

- Match the support overhang threshold angle to the model’s tilt

- No infill is required for these supports

- Limit support height using support enforcers to keep them only where necessary

- Match the support overhang threshold angle to the model’s tilt

-

-

Model Export

3D PRINTINGSTL • STP • DWG

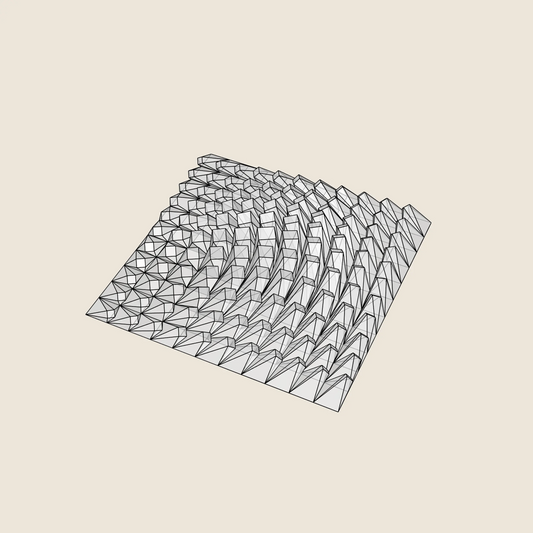

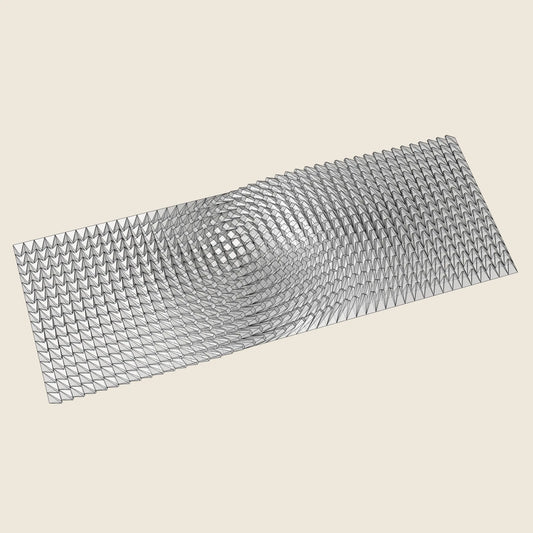

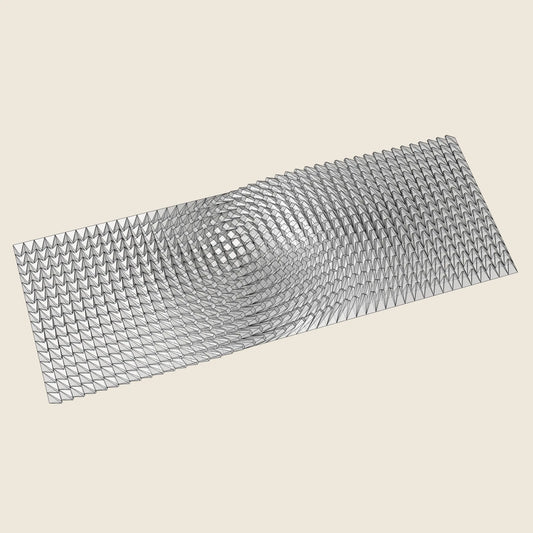

TWISTED BOX - 3D MODEL EXPORT / PARAGAMI 007_001

Regular price $13.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

RANDOM PENTAGONS (3x COLOUR VERSIONS) - 3D MODEL EXPORT / PARAGAMI 007_006

Regular price $13.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

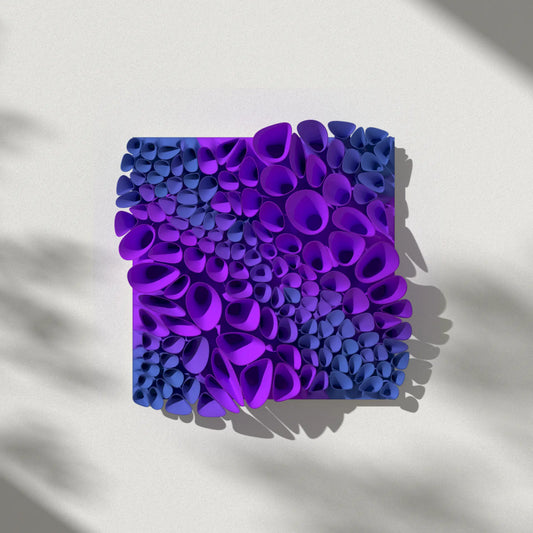

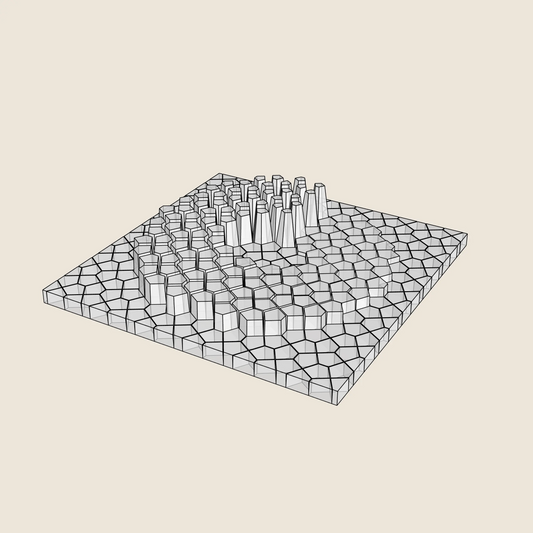

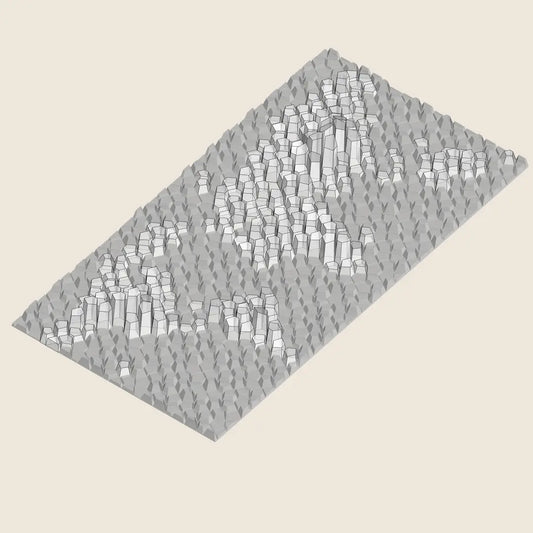

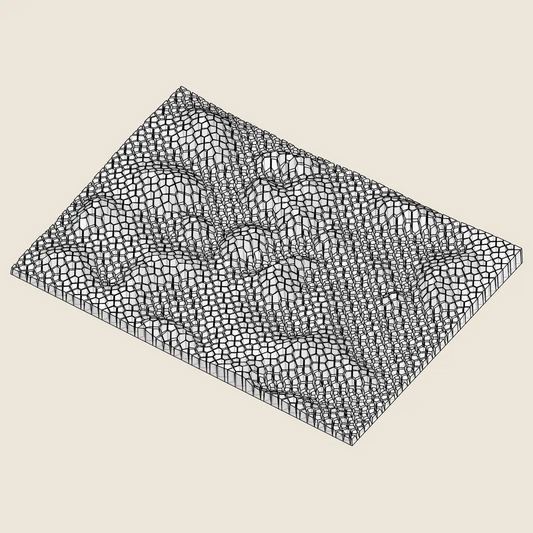

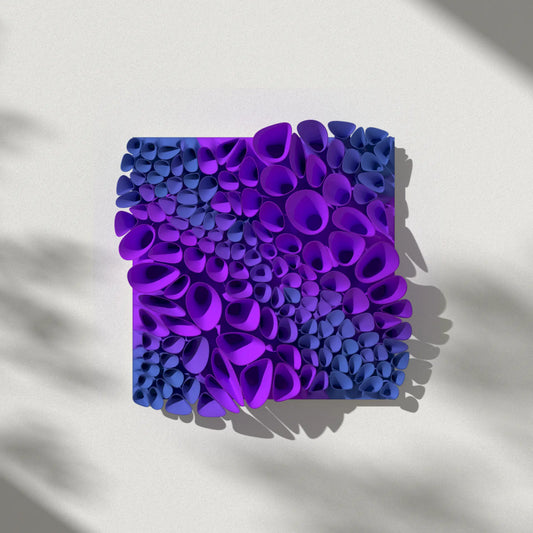

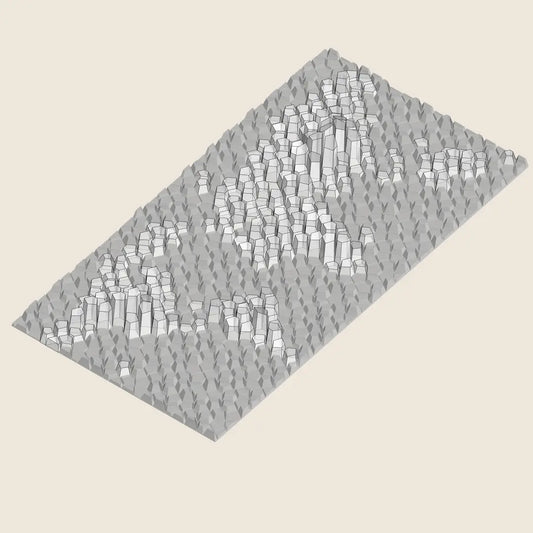

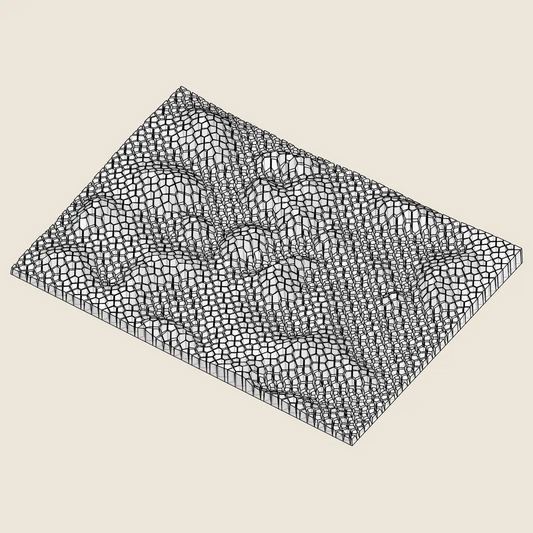

CORAL SPONGE 01 - 3D MODEL EXPORT / PARAGAMI 010_004

Regular price $25.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

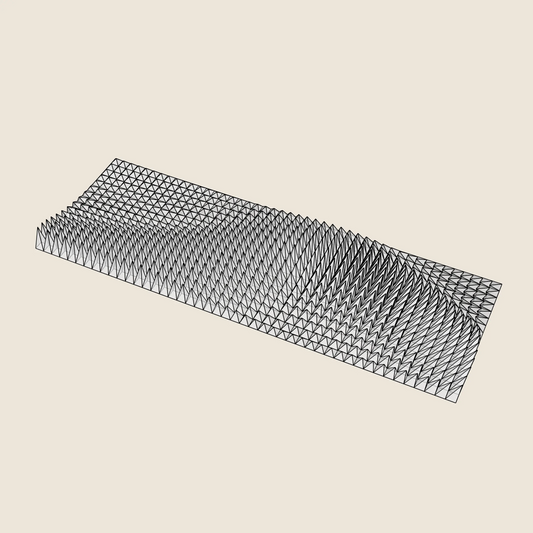

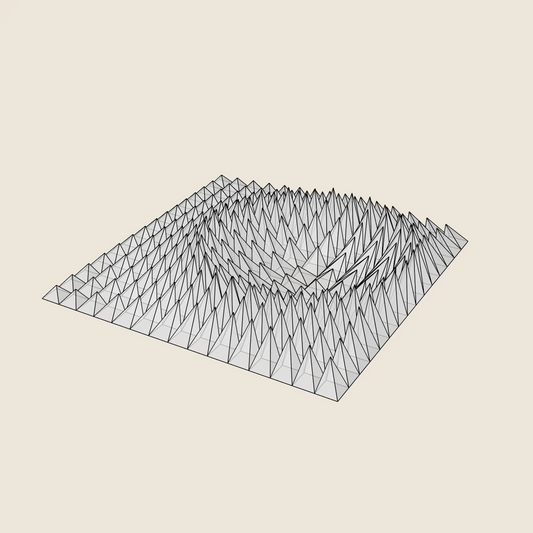

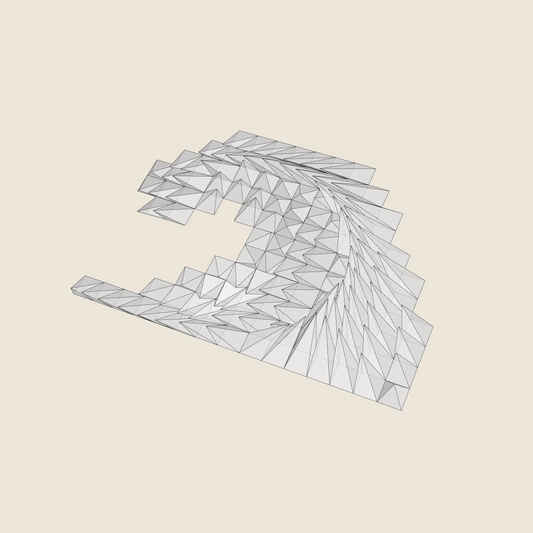

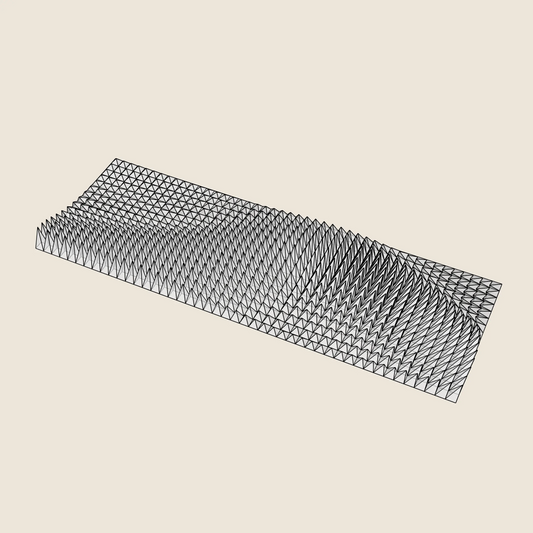

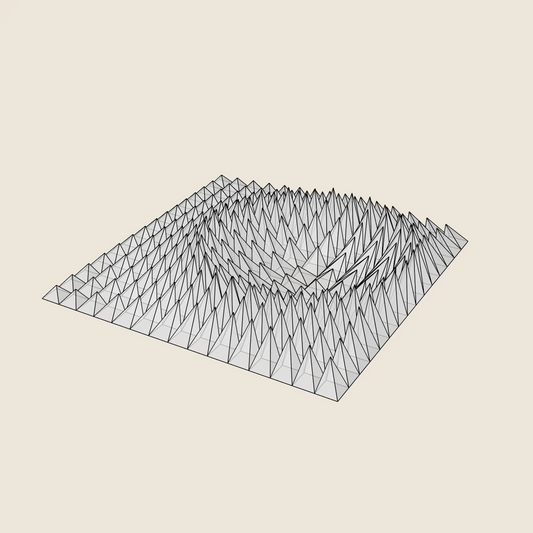

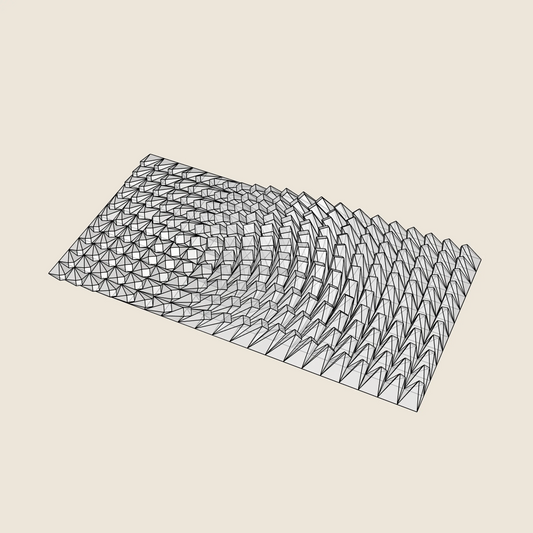

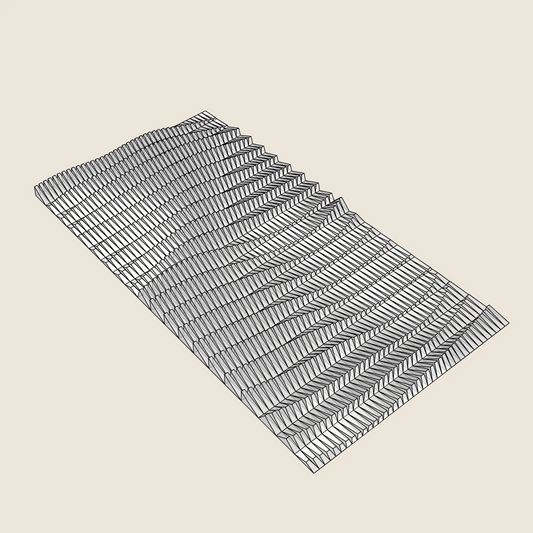

TRIANGLE WAVE - 3D MODEL EXPORT / PARAGAMI 001_002

Regular price $22.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

FLOATING FUMES - 3D MODEL EXPORT / PARAGAMI 010_006

Regular price $19.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

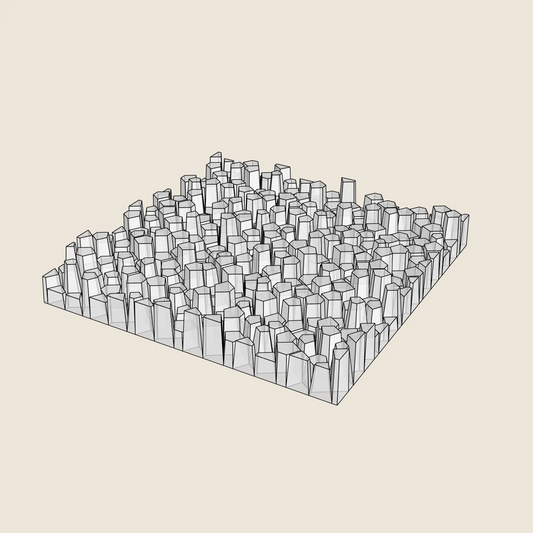

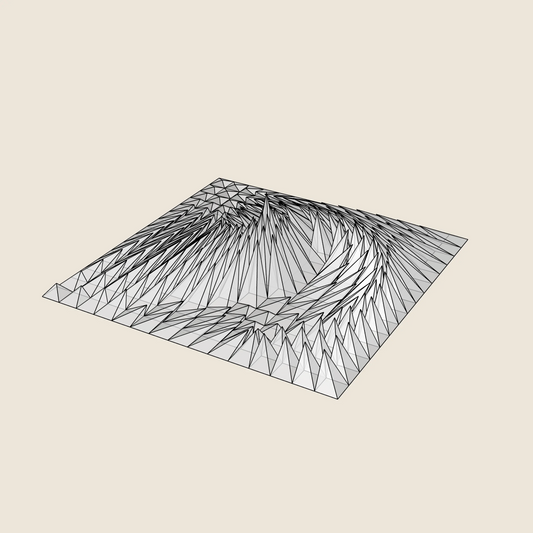

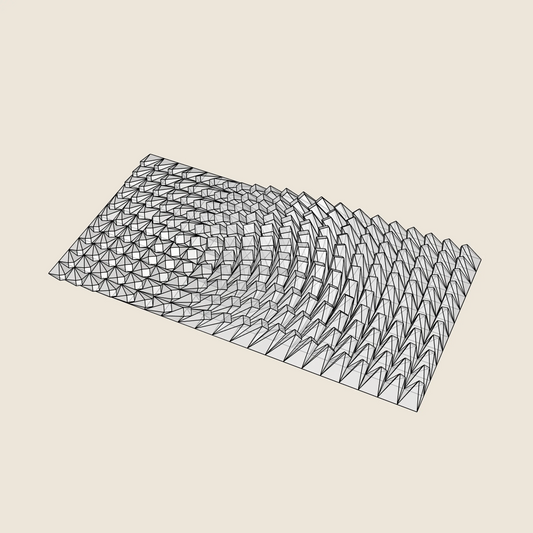

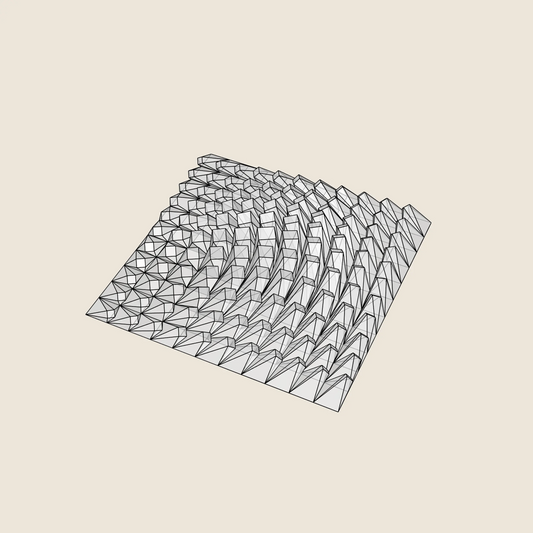

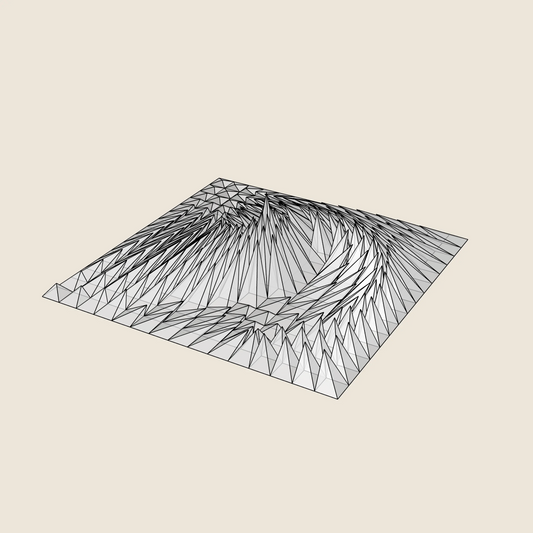

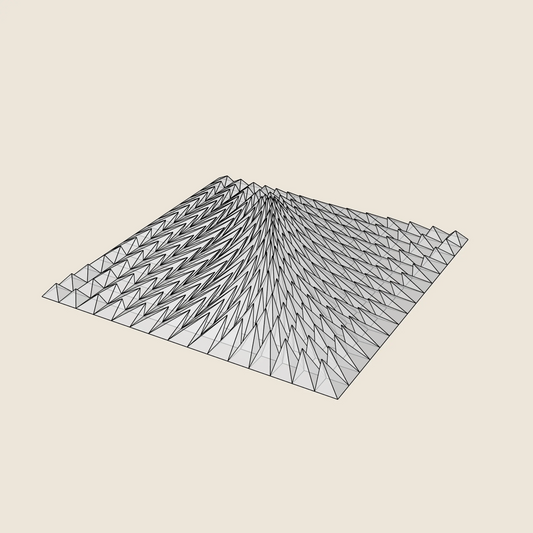

WHIRL PEAK - 3D MODEL EXPORT / PARAGAMI 001_005

Regular price $13.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

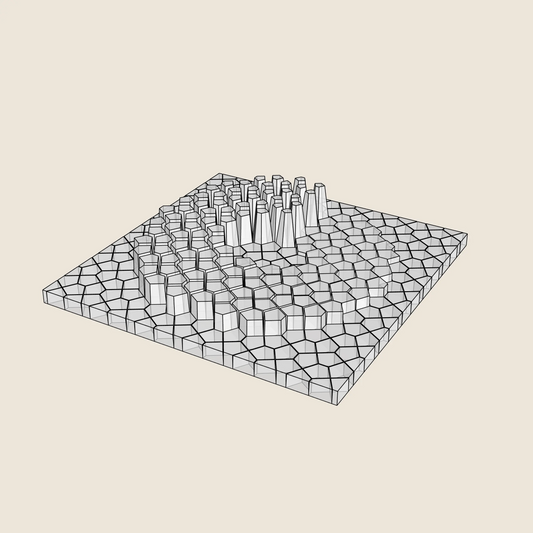

CORAL SPONGE 03 (tileable) - 3D MODEL EXPORT / PARAGAMI 010_011

Regular price $19.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

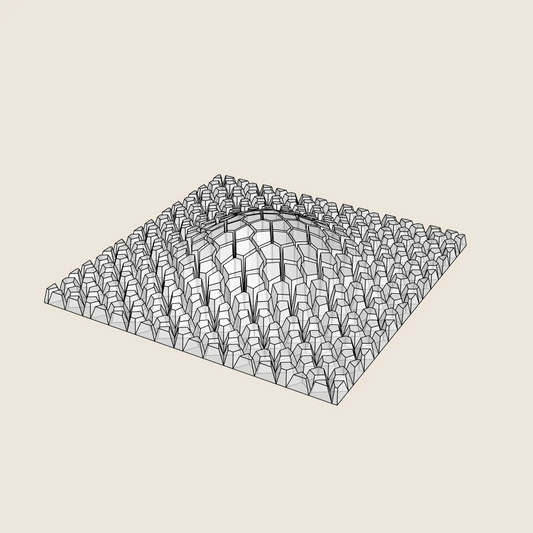

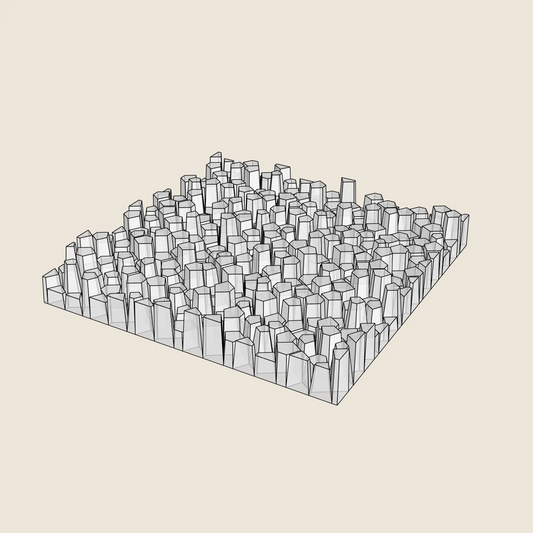

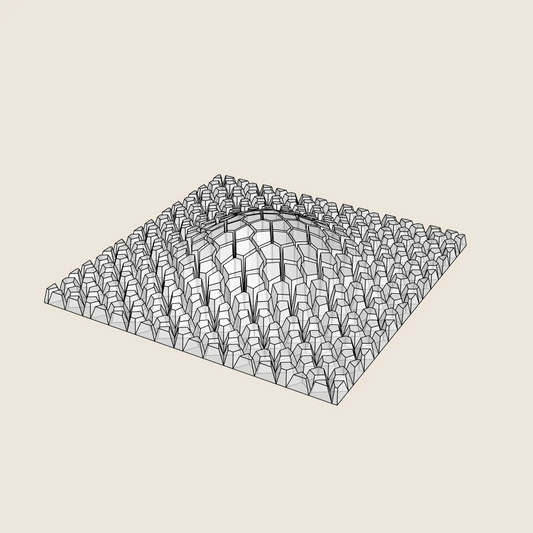

CRACKED BULGE - 3D MODEL EXPORT / PARAGAMI 007_004

Regular price $13.00 USDRegular priceUnit price / per -

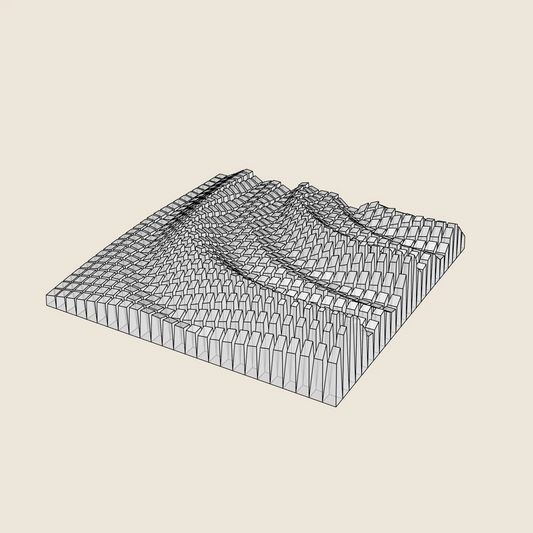

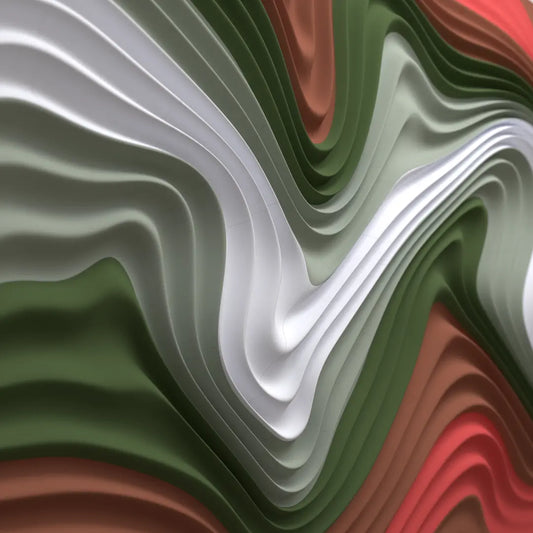

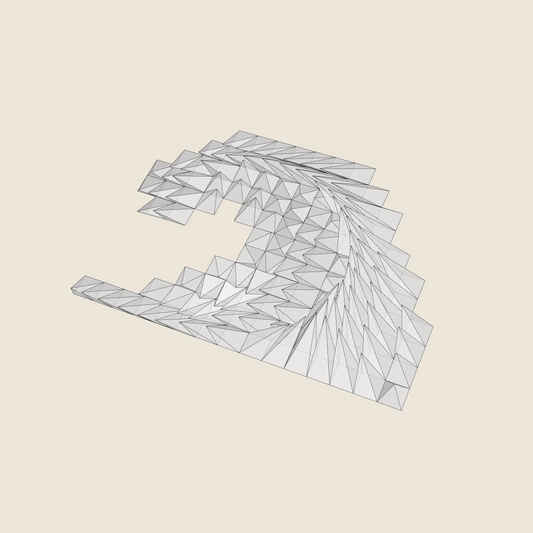

Model Export

3D PRINTINGSTL • STP • DWG

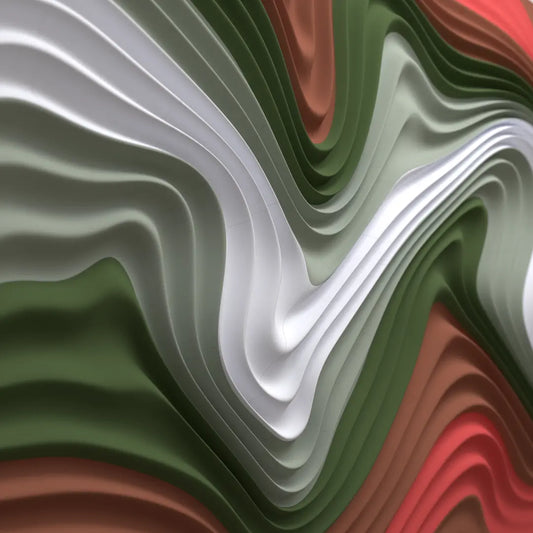

HIGH TIDE - 3D MODEL EXPORT / PARAGAMI 002_003

Regular price $16.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

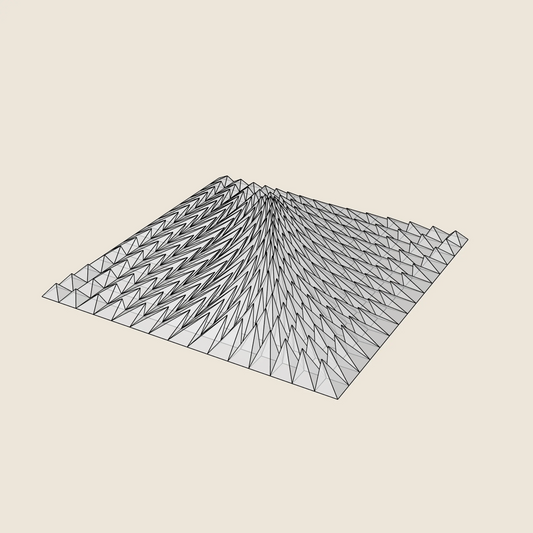

CRATER RING - 3D MODEL EXPORT / PARAGAMI 001_004

Regular price $13.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

SPIRAL RAMP - 3D MODEL EXPORT / PARAGAMI 007_005

Regular price $9.00 USDRegular priceUnit price / per$13.00 USDSale price $9.00 USDSale -

Model Export

3D PRINTINGSTL • STP • DWG

WORLD MAP - 3D MODEL EXPORT / PARAGAMI 007_007

Regular price $19.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

PLUNGING WAVE - 3D MODEL EXPORT / PARAGAMI 001_006

Regular price $7.00 USDRegular priceUnit price / per$13.00 USDSale price $7.00 USDSale -

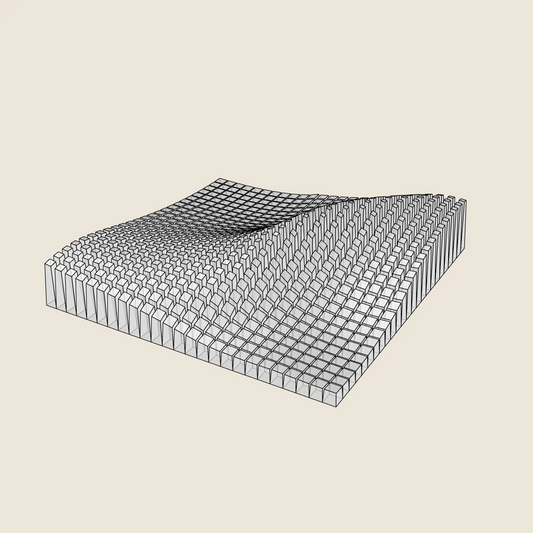

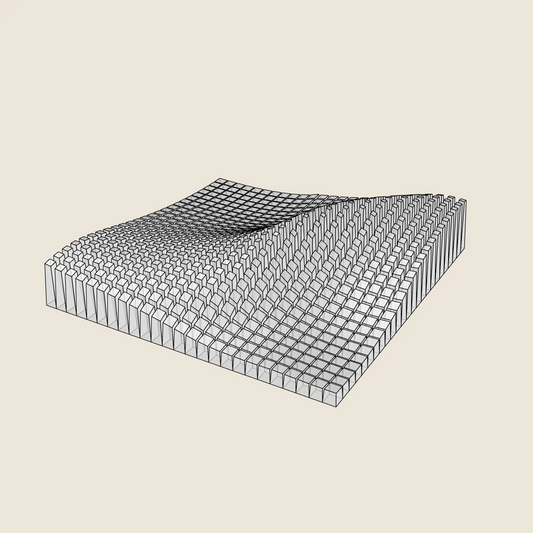

Model Export

3D PRINTINGSTL • STP • DWG

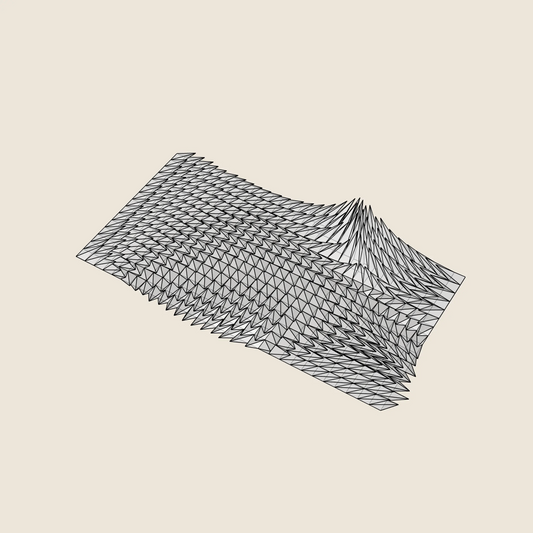

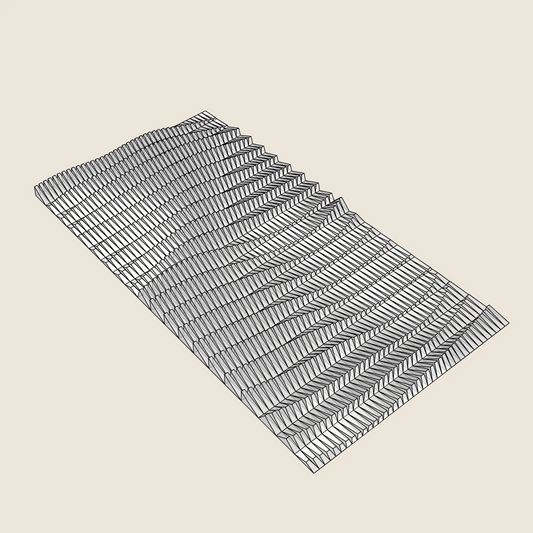

WINDY FUR - 3D MODEL EXPORT / PARAGAMI 001_001

Regular price $16.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

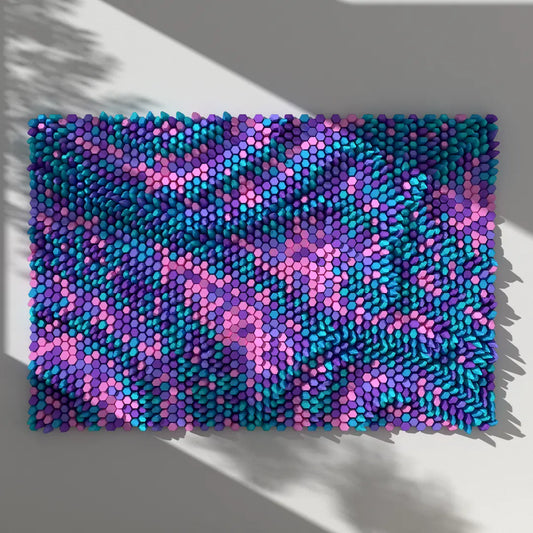

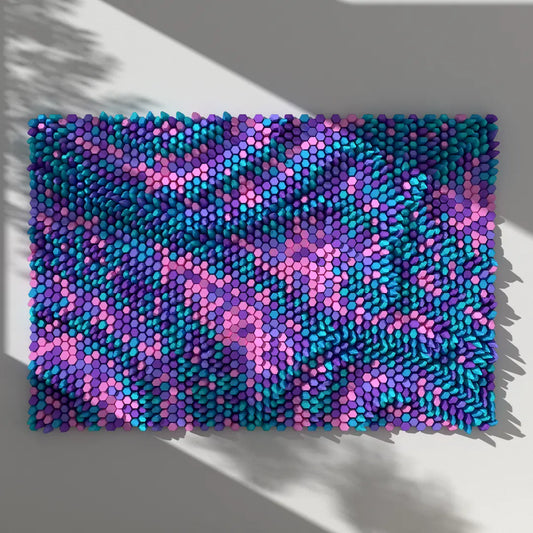

MOSAIC [10 BLOCKS / 25 LAYOUTS] - 3D MODEL EXPORT / PARAGAMI 016_001

Regular price $27.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

TWISTED BOX 03 - 3D MODEL EXPORT / PARAGAMI 007_003

Regular price $19.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

MOSS WALL - 3D MODEL EXPORT / PARAGAMI 007_009

Regular price $19.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

TWISTED BOX 02 - 3D MODEL EXPORT / PARAGAMI 007_002

Regular price $16.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

WHIPPING CREAM - 3D MODEL EXPORT / PARAGAMI 010_001

Regular price $19.00 USDRegular priceUnit price / per -

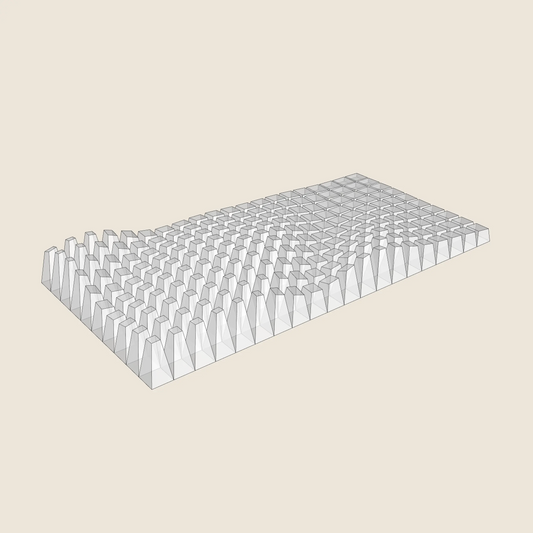

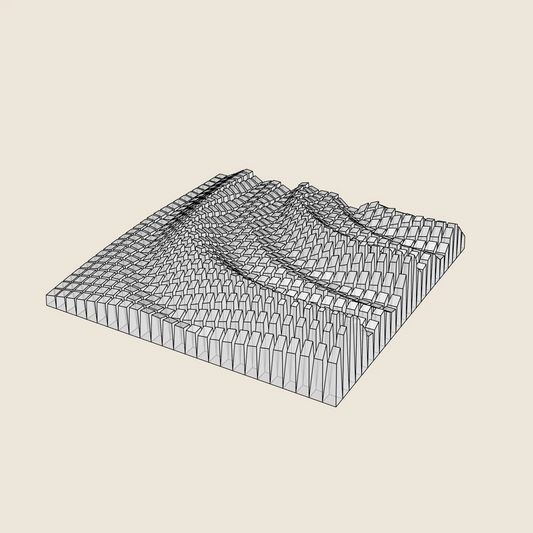

Model Export

3D PRINTINGSTL • STP • DWG

TECTONIC COLLISION - 3D MODEL EXPORT / PARAGAMI 001_003

Regular price $13.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

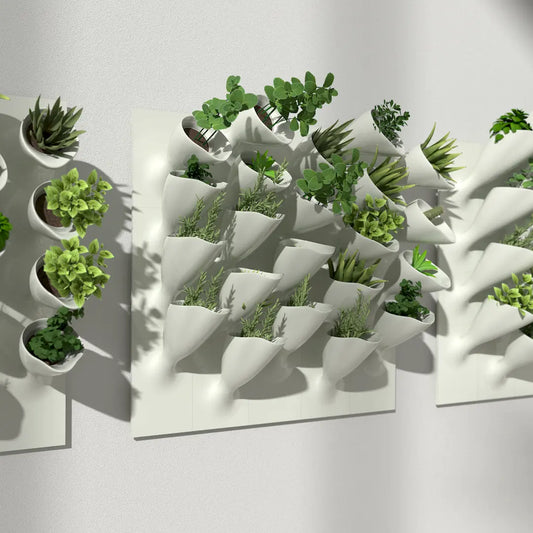

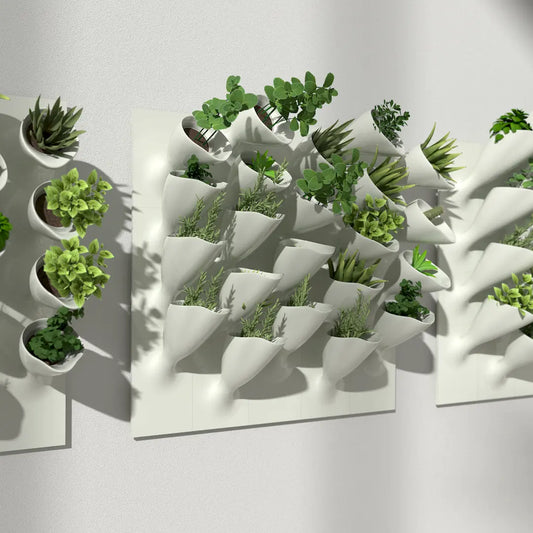

CORNETS DE FLEUR 02 (3× 22 blocks) - 3D MODEL EXPORT / PARAGAMI 010_008

Regular price $15.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

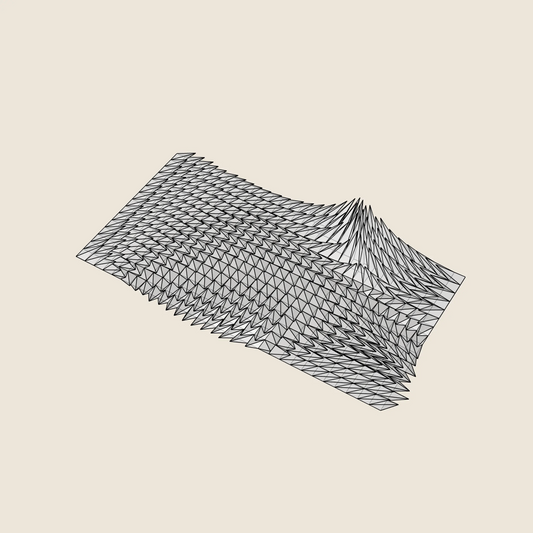

DIAGONAL WAVE - 3D MODEL EXPORT / PARAGAMI 002_005

Regular price $15.00 USDRegular priceUnit price / per$19.00 USDSale price $15.00 USDSale -

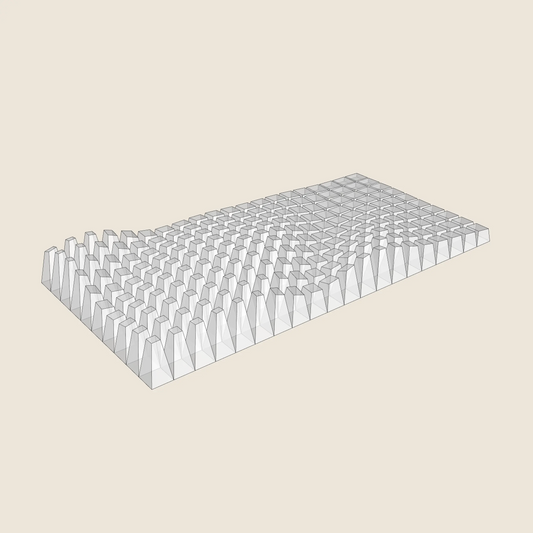

Model Export

3D PRINTINGSTL • STP • DWG

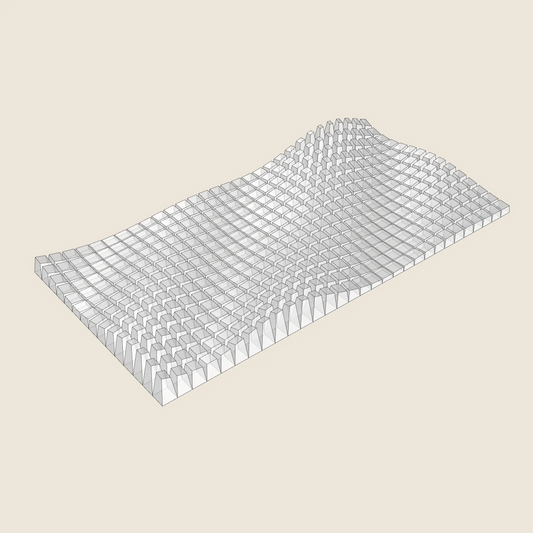

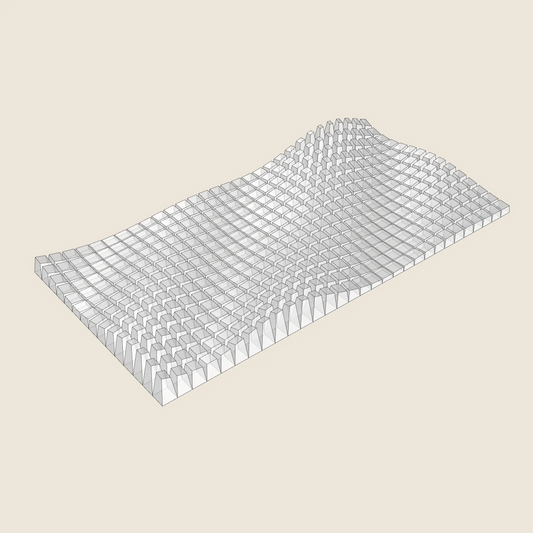

BLOCK WAVE - 3D MODEL EXPORT / PARAGAMI 002_001

Regular price $10.00 USDRegular priceUnit price / per$13.00 USDSale price $10.00 USDSale -

Model Export

3D PRINTINGSTL • STP • DWG

QUARTER CIRCLE WAVES - 3D MODEL EXPORT / PARAGAMI 002_004

Regular price $19.00 USDRegular priceUnit price / per -

Model Export

3D PRINTINGSTL • STP • DWG

PAPER WAVES - 3D MODEL EXPORT / PARAGAMI 006_001

Regular price $19.00 USDRegular priceUnit price / per